Zhejiang Hisun Pharmaceutical Co., Ltd. (hereinafter referred to as "Hisun Pharmaceutical") was founded in 1956 and issued A shares in 2000. In 2012, it established a joint venture with Pfizer in the field of brand generic drugs to establish Hisun Pfizer Pharmaceutical Co., Ltd. It was selected as one of the first batch of "Innovative Enterprises", "National Intellectual Property Demonstration Enterprise", "National Industrial Brand Cultivation Demonstration Enterprise", and was included in the "National Pharmaceutical Industry Top 100 Enterprises" and "China's Chemical Pharmaceutical Industry Top 100 Comprehensive Industrial Enterprises" , "2017 Top 100 International Pharmaceutical Companies".

Headquartered in Taizhou, Hisun Pharmaceuticals has established integrated pharmaceutical bases in Taizhou, Zhejiang, Fuyang, Hangzhou, and Rudong, Jiangsu. The research and development tentacles extend to core cities such as Beijing and Shanghai where knowledge, talent, and technology are intensive. The three major business groups of biopharmaceuticals and general health, with marketing networks covering more than 70 countries and regions around the world, have developed into a "pharmaceutical industry group" consisting of raw materials, preparations, biological drugs, innovative drugs and commercial circulation.

Hisun Pharmaceutical has established a nationally recognized enterprise technology center, a provincial academician workstation, the province's first post-doctoral research workstation with independent recruitment qualifications, and about 1,200 full-time R&D personnel. The research and development and production of drug treatment areas cover anti-tumor, anti-infection, cardiovascular, endocrine, immunosuppression, anti-depression, orthopedics, etc.

Hisun Pharmaceutical provides a full range of support for the growth and entrepreneurship of employees. It has a broad stage in marketing, R&D, technology, manufacturing and management; it provides employees with various work, training and learning opportunities at home and abroad, so As the company grows, employees can also share the success of the company. Persevering in drug innovation, achieving the dream of health and longevity! Hisun looks forward to working hand in hand with you to realize Hisun's global and sustainable medical Chinese dream.

use

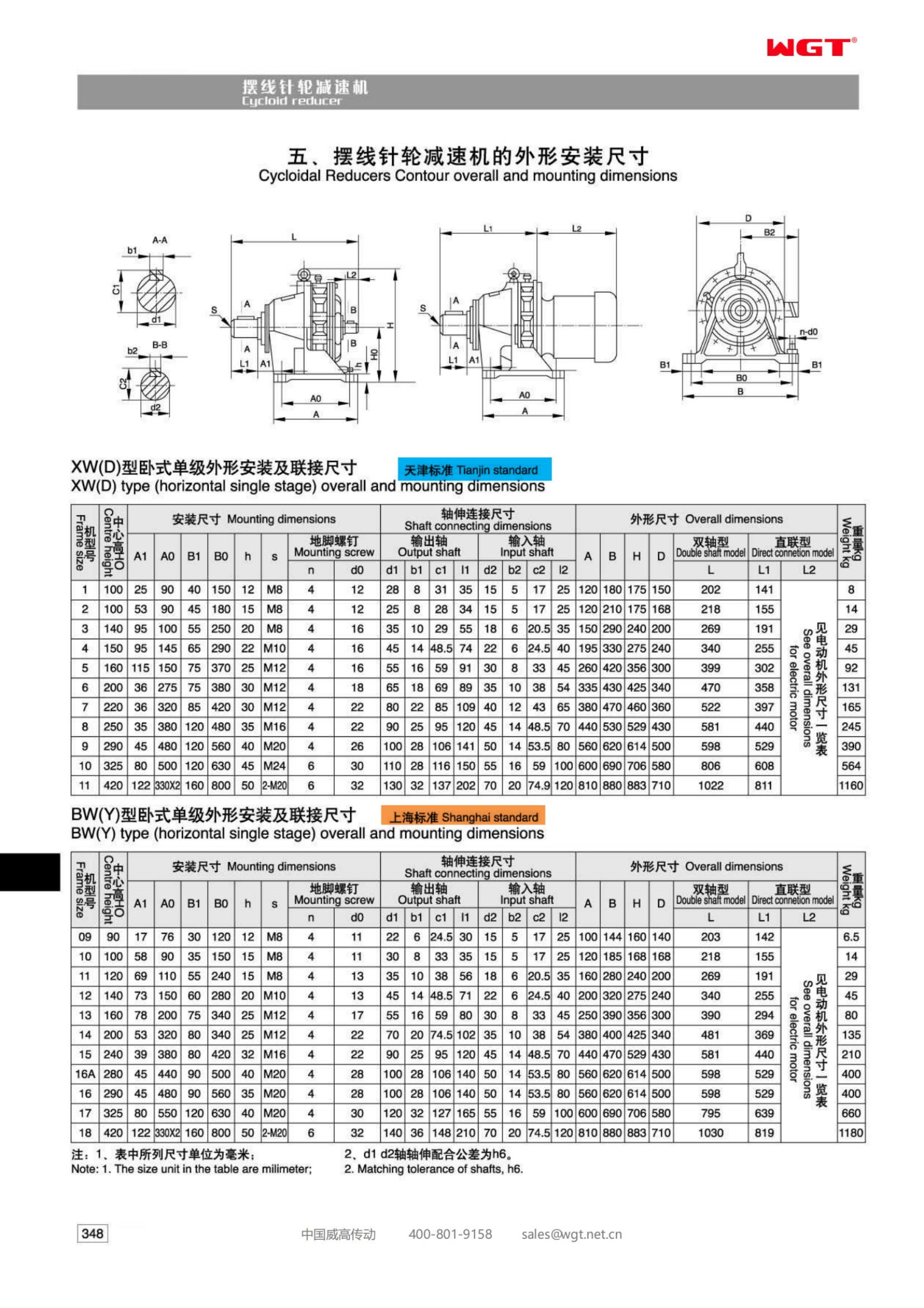

Cycloidal pin gear reducer adopts the principle of cycloidal pin tooth meshing and planetary transmission, so it is usually called planetary cycloid reducer. Planetary cycloidal pin gear reducer can be widely used in petroleum, environmental protection, chemical industry, cement, transportation, In textile, pharmaceutical, food, printing, lifting, mining, metallurgy, construction, power generation and other industries, as a drive or decelerating device, the machine is divided into horizontal, vertical, double-shaft and direct-connected assembly methods. Its unique and stable structure can replace ordinary cylindrical gear reducers and worm gear reducers in many cases. Therefore, planetary cycloid reducers are widely used in various industries and fields and are generally welcomed by users.

Conditions of Use

1. Cycloidal pinwheel reducers are allowed to be used in continuous work situations, while allowing both forward and reverse rotation. Some models of cycloid reducers only allow one-way rotation.

2. The rated speed of the input shaft is 1500 rpm. When the input power is greater than 18.5 kW, it is recommended to use a 6-pole motor with 960 rpm.

3. The working positions of the horizontally installed cycloid reducer are all horizontal. The maximum horizontal tilt angle during installation is generally less than 15°. When it exceeds 15°, other measures should be taken to ensure adequate lubrication and prevent oil leakage.

4. The output shaft of the cycloid reducer cannot be subjected to large axial and radial forces. Other measures must be taken when there is a large axial force and radial force.

lubricating

1. The horizontal cycloid reducer adopts oil pool lubrication under normal conditions, and the oil level can be kept in the middle of the oil window. When the working conditions are bad and the ambient temperature is high, the circulating lubrication can be used.

2. Cycloid pinwheel reducer generally chooses 40# or 50# mechanical oil lubrication at room temperature. In order to improve the performance of the reducer and extend the service life of the cycloid pinwheel reducer, it is recommended to use 70# or 90# extreme pressure gears. Oil, lubricating oil should be reconsidered when working at high and low temperatures.

3. The vertical installation of planetary cycloid reducer should strictly prevent the oil pump from cutting off the oil to avoid damage to the parts of the reducer.

4. When refueling, you can turn the breather cap on the upper part of the seat to refuel. When draining the oil, turn the drain plug at the bottom of the main seat to drain the dirty oil. There is no lubricating oil inside the reducer when it leaves the factory.

5. New oil should be replaced for 100 hours after the first refueling operation, (and clean the internal dirty oil), then continue to work afterwards, and replace it every six months (8-hour work system). If the working conditions are bad, the oil change time can be appropriately shortened. Practice has proved that frequent cleaning and oil change of the reducer (such as 3-6 months) play an important role in extending the service life of the reducer. Lubricating oil should be replenished frequently during use.

6. The factory-made reducer has been greased and replaced every six months. The grease adopts aluminum disulfide-2# or 2L-2# lithium-based lubricating grease.

installation

1. When installing couplings, belt pulleys, sprocket and other coupling parts on the output shaft of the cycloid reducer, direct hammering is not allowed, because the output shaft structure of the reducer cannot withstand the axial hammering force. You can use the shaft end screw hole to screw the screw into the coupling piece.

2. The shaft diameters of the output shaft and input shaft are matched with GB1568-79.

3. The eyebolts on the reducer are only for lifting the reducer.

4. When the reducer is installed on the foundation, the elevation of the installation center line of the reducer, the levelness and the relevant dimensions of the connected parts should be calibrated. The concentricity of the calibrated moving shaft should not exceed the allowable range of the coupling.

5. When the reducer is calibrated, it can be carried out with steel spacers or cast iron spacers. The height of the spacers is not more than three, and it can also be carried out with a contract iron, but the reducer should be replaced with flat spacers after calibration.

6. The configuration of the cushion block should avoid causing deformation of the machine body, and should be arranged symmetrically on both sides of the foundation bolts, and the mutual distance can be enough to allow the water slurry to flow freely during irrigation.

7. The irrigation of cement slurry should be dense, without bubbles, voids and other defects.