Introduction of Shougang Group

Shougang has a production system that includes coking, sintering, iron-making, steel-making and rolling, and its main production equipment has reached the international advanced level in the same industry. The annual production capacity of finished steel is more than 3.2 million tons, including 1.2 million tons of ordinary hot-rolled wire rod and 2 million tons of high-speed non-twist controlled cold-rolled hot-rolled wire rod. The main product is wire, which can produce ∮5.5-14mm wire products. According to the carbon content, it can be divided into low carbon steel, medium carbon steel and high carbon steel, as well as special purpose steel, including cold heading steel, welding rod steel, prestressed steel, spring steel, etc. It can also produce steel window wire, steel wire, steel stranded wire, steel nails, welding rods, etc.

The reducer is a commonly used power transmission mechanism. The speed reduction mechanism reduces the higher speed to the required speed and obtains a larger torque. In the current mechanism used to transmit power and motion, the application range of the reducer is quite wide. It can be seen in almost all kinds of mechanical transmission systems, from ships, automobiles, locomotives, heavy machinery used in construction, processing machinery and automatic production equipment used in the machinery industry, to common daily life Home appliances, clocks, etc. The application of the reducer can be seen from the transmission of large power, to the transmission of small loads, and the precise angle transmission. In industrial applications, the reducer has the function of reducing speed and increasing torque. Therefore, it is widely used in speed and torque conversion equipment. The main functions of the reducer are:

(1) Decrease speed and increase output torque at the same time. The torque output ratio is the motor output multiplied by the reduction ratio, but it must not exceed the rated torque of the reducer.

(2) Deceleration reduces the inertia of the load at the same time, and the reduction in inertia is the square of the reduction ratio.

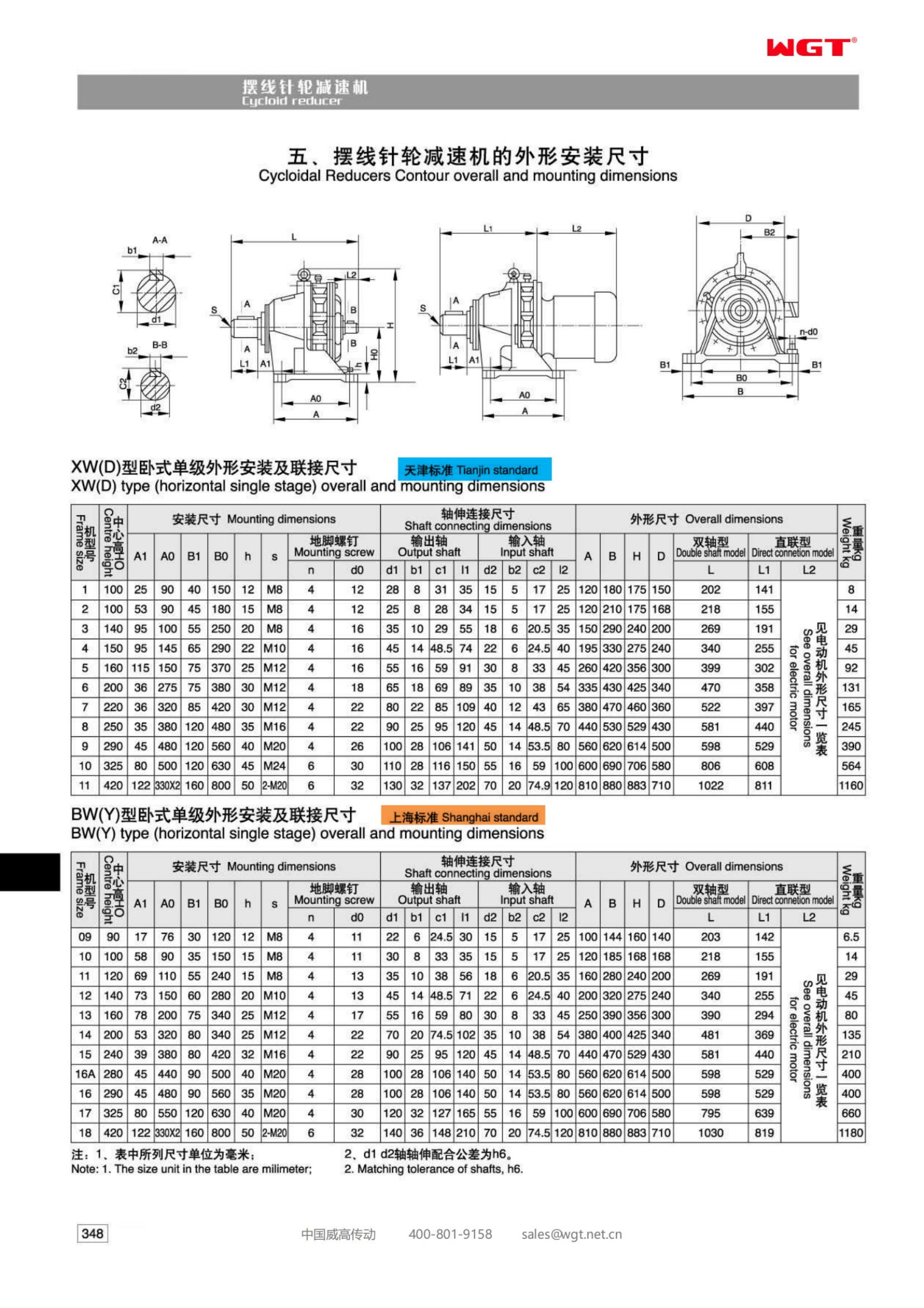

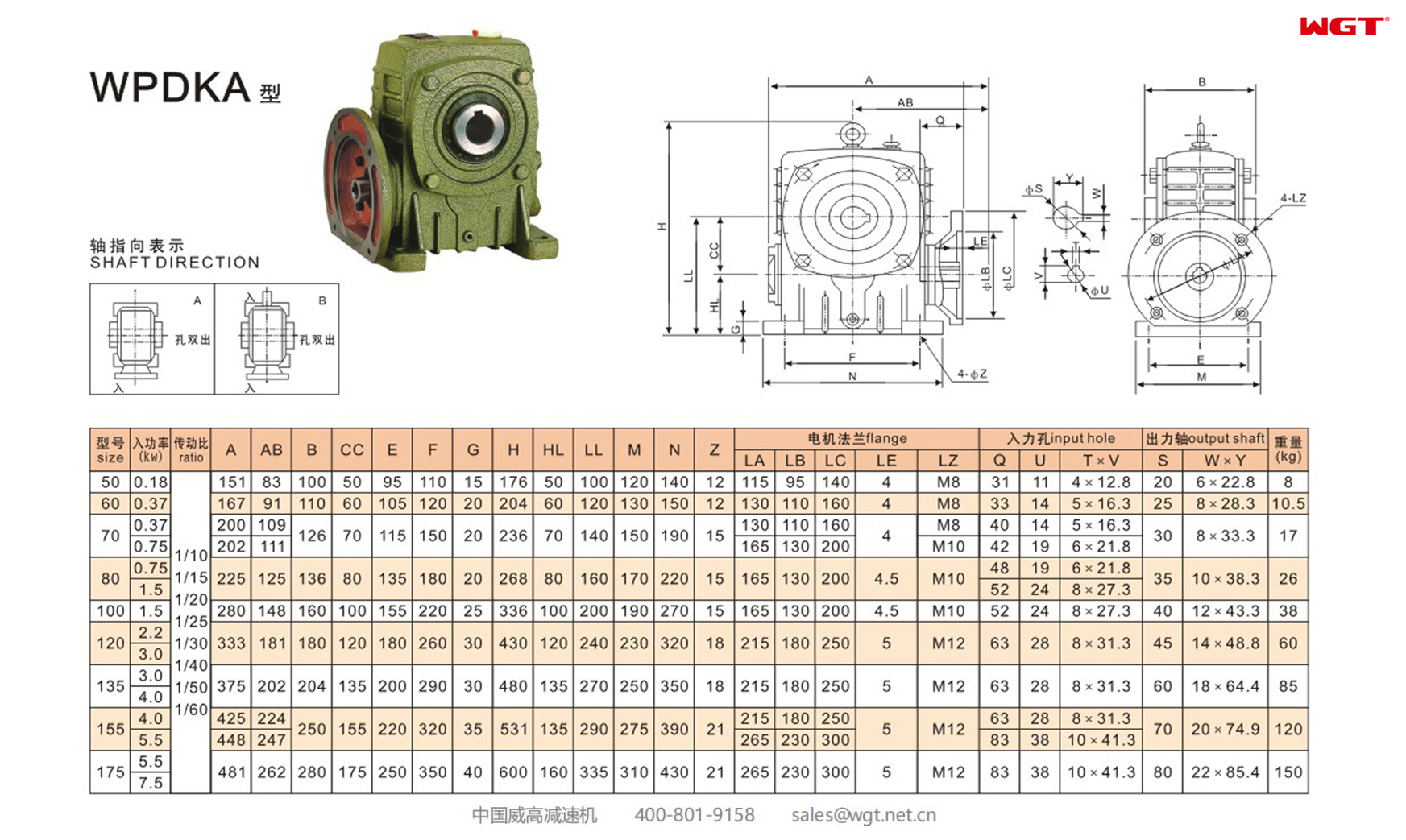

Common types of reducers are: gear reducers, worm gear reducers, cycloid pinwheel reducers, planetary gear reducers, stepless speed reducers, etc.

Reducers are widely used in iron and steel production enterprises. At the same time, due to the relatively harsh environment of use, problems such as wear of the bearing position in the bearing chamber and oil leakage on the joint surface of the reducer during operation sometimes occur. Due to the high degree of automation and continuity of modern steel production, once the above problems occur, if there are no advanced maintenance methods, it will inevitably cause waste of manpower and financial resources, and even the entire production line will stop production, causing significant economic losses.

Case analysis of reducer repair:

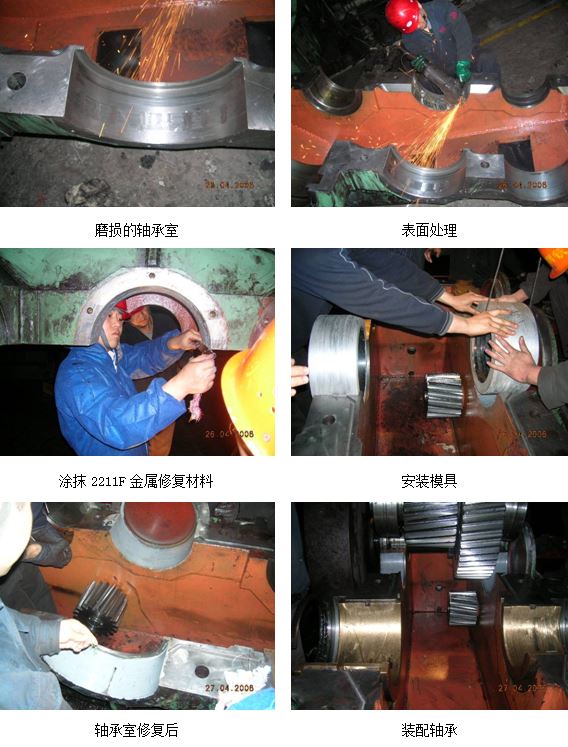

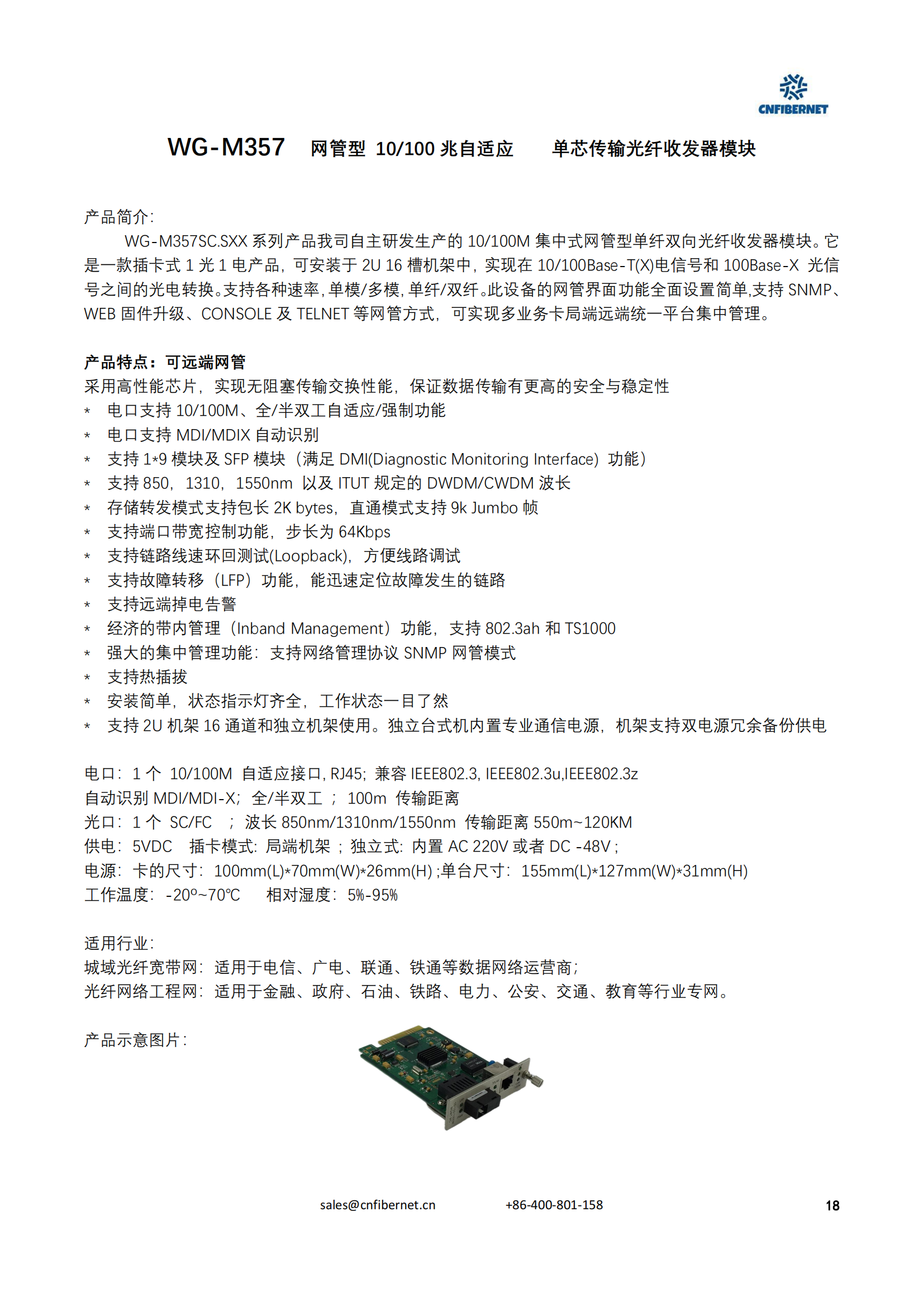

Case 1: Wear of bearing chamber of 650-ton cold shear

The bearing room of the reducer of the cold shear is worn out. After the problem occurs, the traditional method cannot be solved on the spot. It must be repaired by outsourcing. It requires a long time to stop production and waste the valuable production time of the enterprise. Moreover, metal is used to repair the metal, which cannot change the "hard-to-hard" coordination relationship. Under the combined action of various forces, it will still cause wear again.

Fu Shilan 2211F polymer composite material has super adhesion, excellent compressive strength and other comprehensive properties. The use of 2211F polymer composite material can avoid disassembly and machining, and quickly and effectively repair the wear of the bearing chamber. That is, there is no thermal stress of repair welding, and the repair thickness is not limited. At the same time, the product has a retreat that the metal material does not have, absorbs the shock and vibration of the equipment, and avoids the possibility of wear again.

Case 2: Wear of gear shaft diameter of 1450 rolling mill reducer

The bearing position of the gear shaft of the reducer is worn. After the problem occurs, it needs to be repaired by welding or brushing and machining according to the traditional method. However, the thermal stress caused by the high temperature of repair welding cannot be completely eliminated, and it is easy to break during operation; electric brush plating is limited by the thickness of the coating, and it is easy to peel off; and the above methods use metal to repair the metal, which cannot change the "hard-to-hard" The coordination relationship, under the combined action of various forces, will still cause wear again.

Fu Shilan 2211F metal repair material has super adhesion, excellent compressive strength and other comprehensive properties. It can repair gear shaft bearing wear through machining methods, that is, there is no thermal stress of repair welding, and the repair thickness is not limited. It has the concessionability that metal materials do not have, can absorb the shock and vibration of the equipment, avoid the possibility of re-wear, and greatly extend the service life of equipment components (including bearings), save a lot of downtime for enterprises, and create huge economic value; It avoids scrapped replacement and optimizes the maintenance resources within the enterprise.

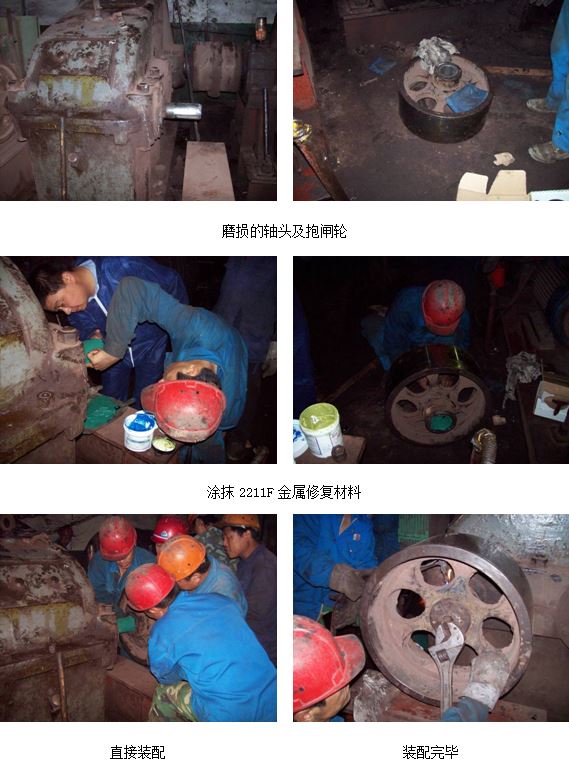

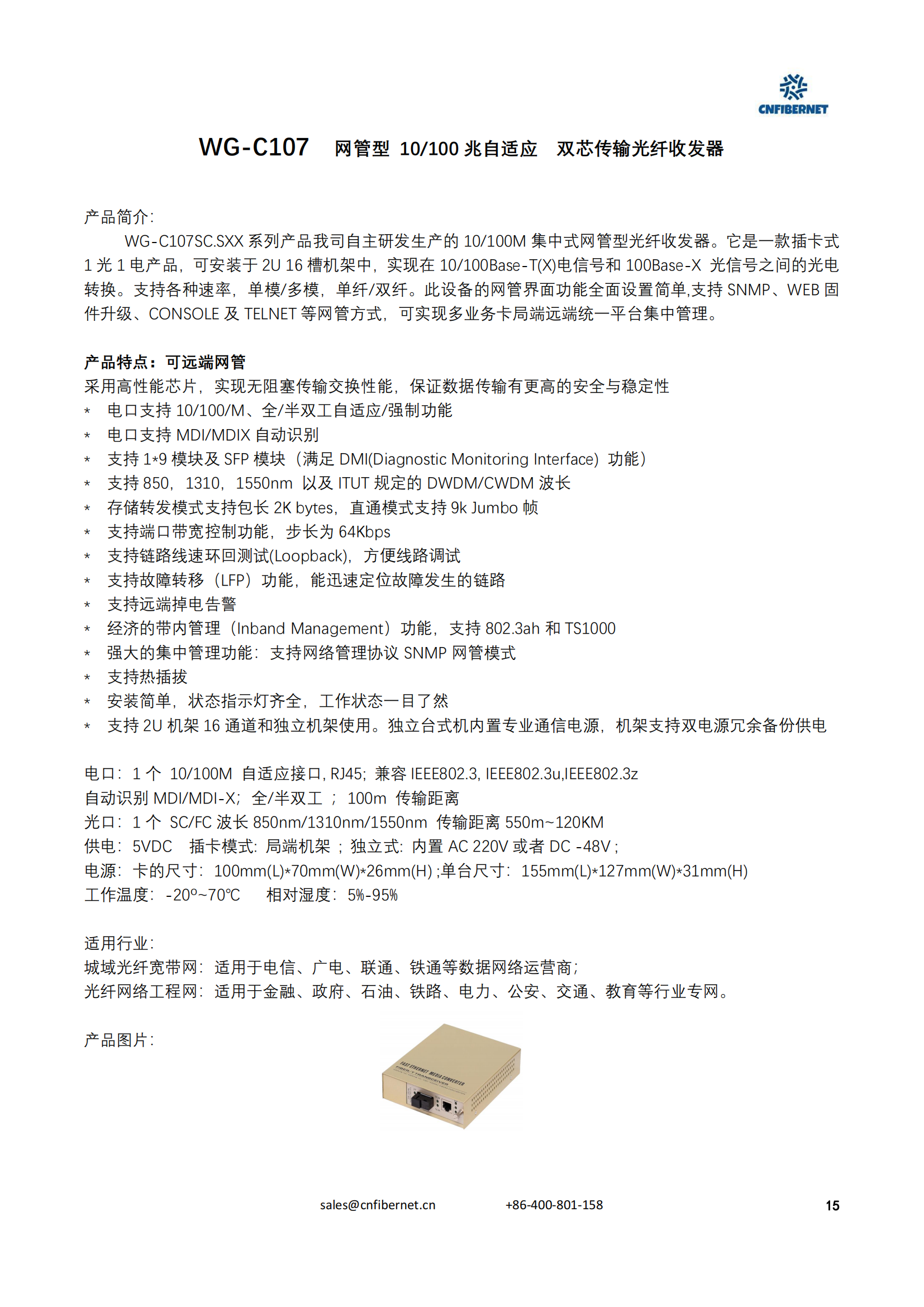

Case 3: Wear of brake shaft head and damage of keyway of blast furnace winch reducer

In the long-term operation of the winch reducer, the brake shaft head is worn and the keyway is damaged. After the problem occurs, the traditional method cannot be solved on the spot, and it must be repaired by outsourcing; and the metal is used to repair the metal, which cannot change the "hard-to-hard" Under the combined action of various forces, the matching relationship between the two will still cause wear again.

Fuschlan 2211F metal repair material has super adhesion, excellent compressive strength and other comprehensive properties. The use of Fuschlan polymer composite material can avoid disassembly and machining, and quickly and effectively repair shaft head and keyway wear. That is, there is no thermal stress of repair welding, and the repair thickness is not limited. At the same time, the product has a retreat that the metal material does not have, absorbs the shock and vibration of the equipment, and can make 100% contact with the mating surface, avoiding the possibility of wear again.

Case 4: Single-roller crusher reducer shaft head wear

The gear shaft head of the single-roll crusher reducer is worn out due to various factors. After the problem occurs, according to the traditional method, the size of the shaft head should be repaired by repair welding or electric brush plating. However, the thermal stress caused by the high temperature of repair welding cannot be completely eliminated, and the shaft is prone to breakage during operation; while the electric brush plating and spraying are limited by the thickness and are easy to peel off.

Fuschlan 2211F polymer composite material has super adhesion, excellent compressive strength and other comprehensive properties. The use of Fuschlan polymer composite material can avoid disassembly and machining, and quickly and effectively repair shaft head wear. That is, there is no thermal stress of repair welding, and the repair thickness is not limited. At the same time, the product has a retreat that the metal material does not have, absorbs the shock and vibration of the equipment, and can make 100% contact with the mating surface, avoiding the possibility of renewed wear.

Case 5: Leakage on the joint surface of the reducer

During the long-term operation of the reducer, due to vibration, abrasion, pressure, temperature, and repeated disassembly and assembly, oil leakage at the static seal of each joint surface is very common, resulting in a large amount of waste of oil, and affecting the site of the enterprise management. The traditional treatment method is to disassemble and open the reducer, replace the sealing gasket or apply the sealant, which is time-consuming and laborious, and it is difficult to ensure the sealing effect, and leakage will occur again during operation.

The use of Fuschlan, Fuschlan 25551 fast curing repair agent and Fuschlan 3223 high-strength modified polyurethane rubber composite materials and technology for on-site treatment of leakage, without disassembly, using polymer composite materials to treat leakage externally, saving time and effort, and the effect is immediate. Its products have superior adhesion, oil resistance and 350% elongation, overcome the impact of the vibration of the reducer, and solve the problems that have not been solved for many years.

1. Leakage of driving reducer